Informação básica

| Modelo Nº. | WNS6-1.25-YQ |

| Posicionamento do Tambor | Caldeira Horizontal |

| Pressão | Pressão |

| Nível de Fabricação | A |

| Estilo de gravação | Caldeira de Combustão de Câmara |

| Uso | Industrial, Casa, Veículo, Central Elétrica |

| Pacote de transporte | Nu com filme plástico |

| Marca comercial | ALCANCE A CALDEIRA |

| Origem | China |

| Código HS | 8402190000 |

| Capacidade de produção | 5000 ton/ano |

Descrição do produto

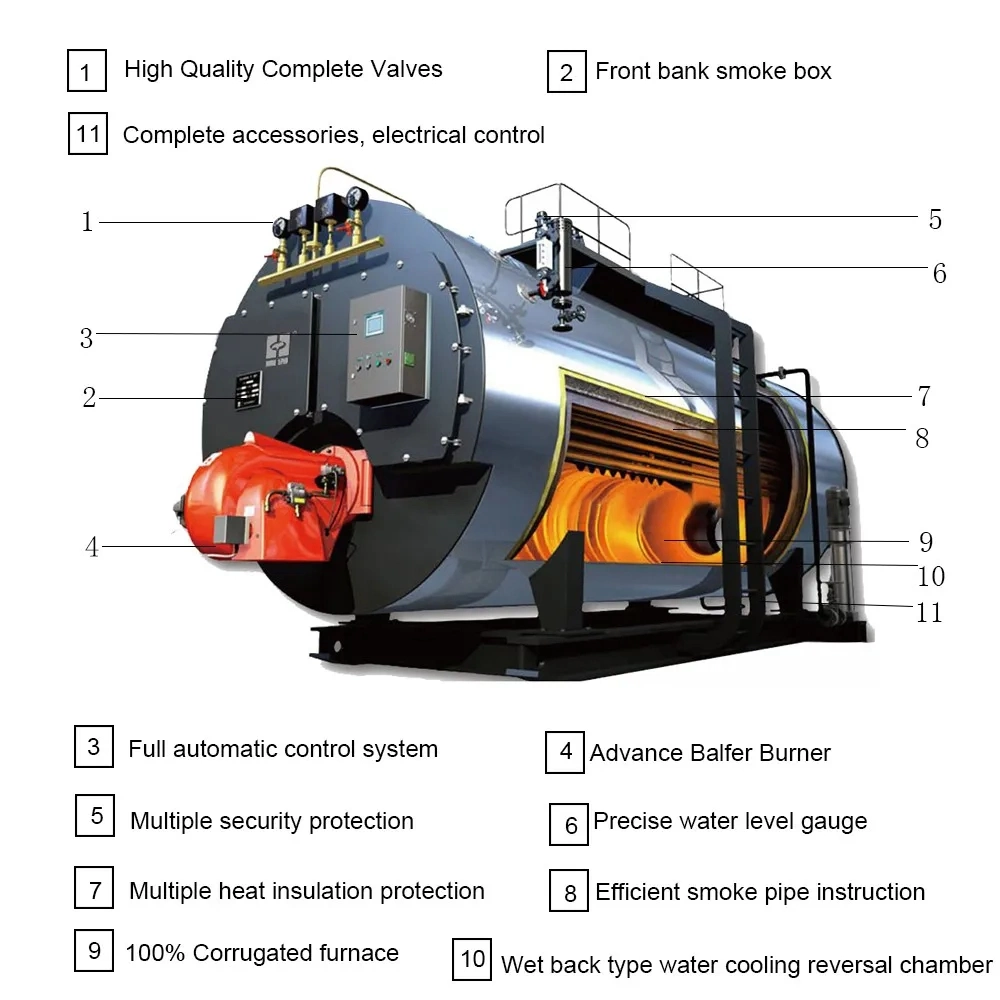

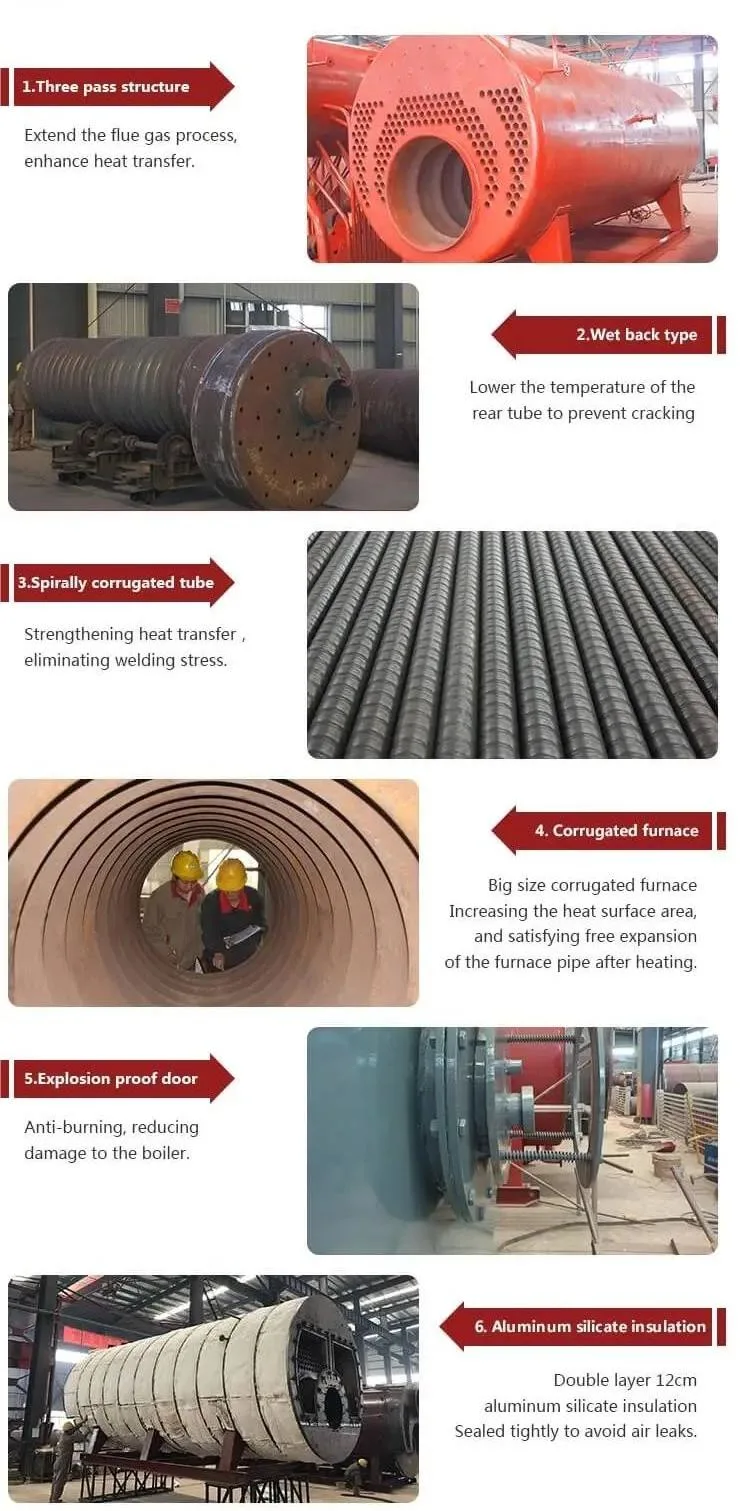

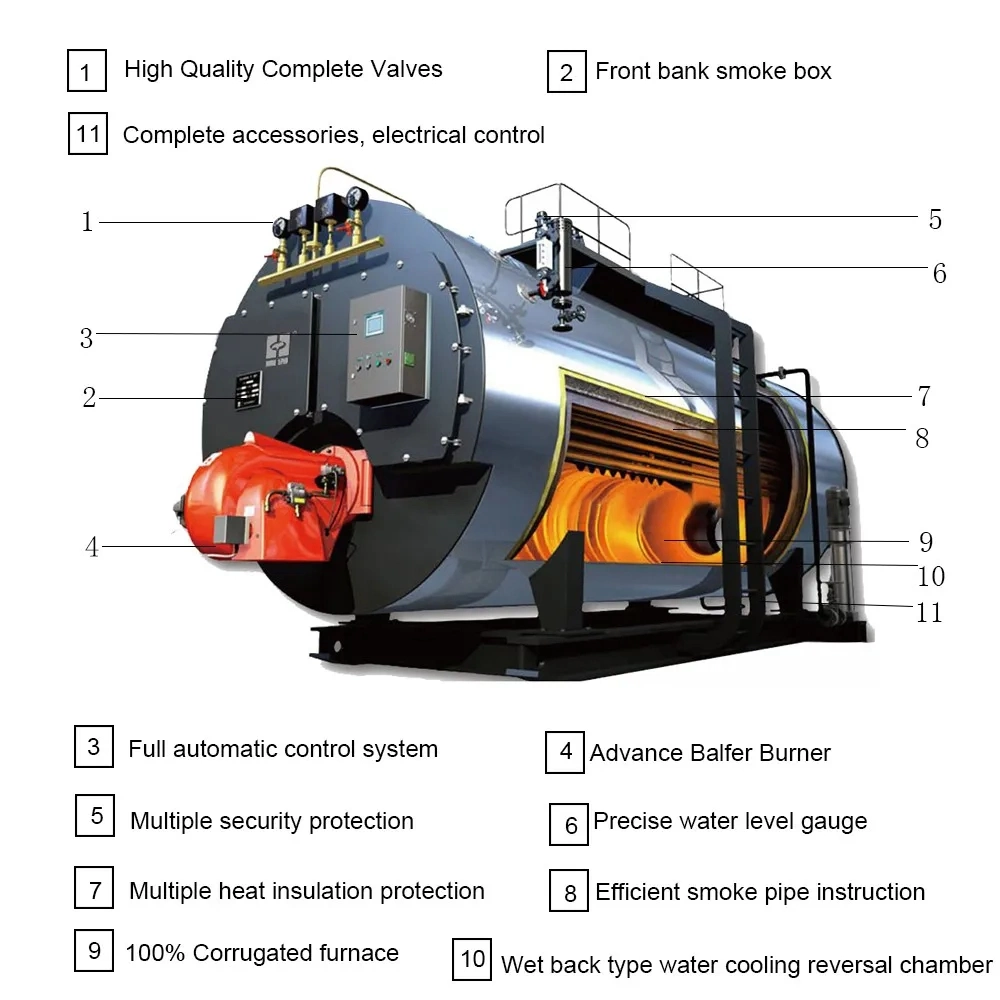

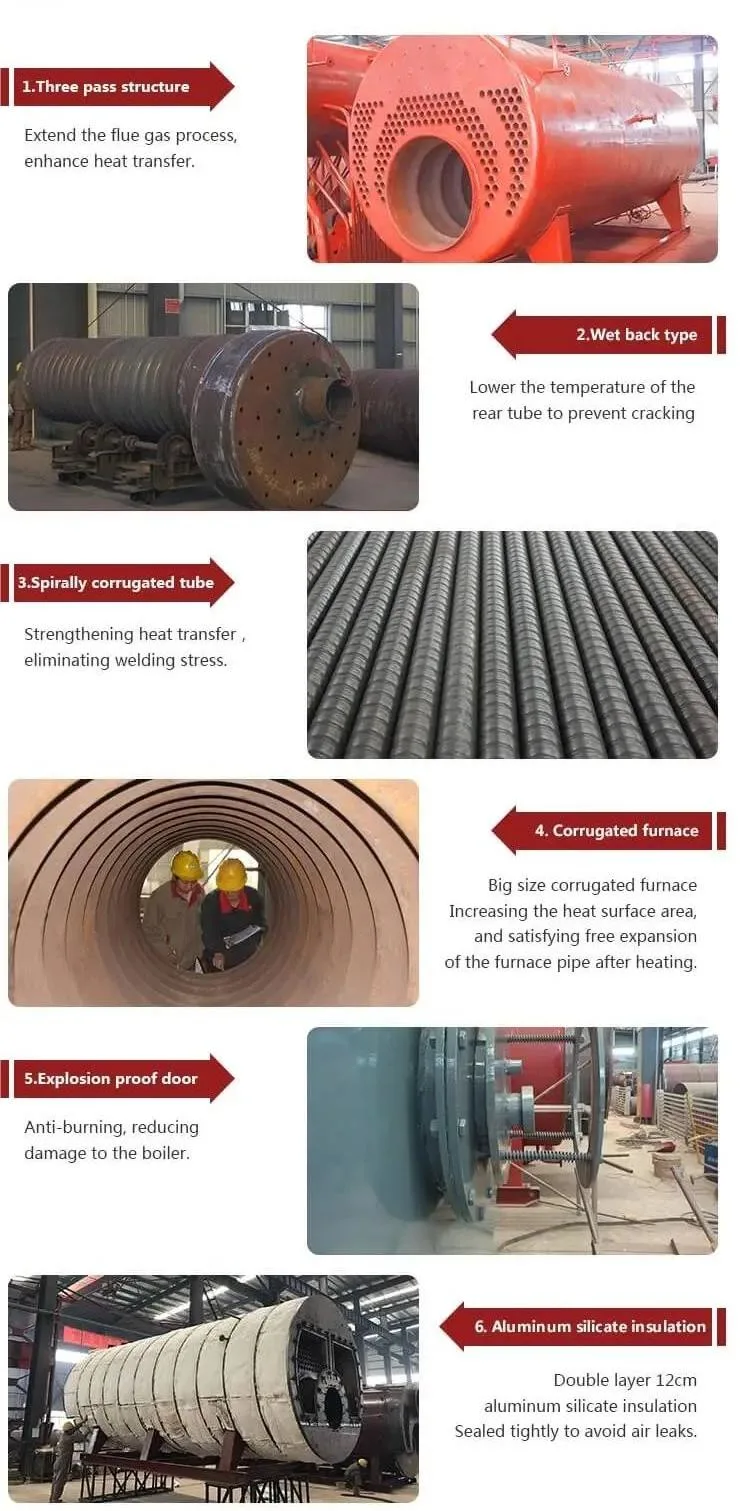

Principais características 1. A caldeira a óleo é industrialmente projetada e presta atenção aos detalhes, ajudando os clientes a economizar tempo e custos. 2. Com seu próprio laboratório, todas as soluções de caldeira a óleo são baseadas em dados experimentais. 3. A caldeira a óleo é segura e ambiental. produtos de economia de energia amigáveis. 4. Fornecer consulta on-line 24 horas de caldeira a óleo. 5. Mais de 30 anos de experiência na indústria de caldeiras a óleo. As soluções personalizadas de caldeira a óleo são baseadas em sua indústria e respectivo caso. 7. A solução certa de caldeira a óleo pode reduzir o custo de entrada do equipamento e os custos operacionais.

Nº do modelo | WNS0,5-1,0-Y/Q | WNS0,7-1,0-Y/Q | WNS1.0-1.0

/1,25-Y/Q | WNS1.5-1.0/1.25

-S/Q | WNS2-1.25/1.6/2.5

-S/Q | WNS3-1.25/1.6/2.5

-S/Q | WNS4-1.25/1.6/2.5

-S/Q | WNS5-1.25/1.6/2.5

-S/Q |

Evaporação nominal

(º) | 0,5 | 0,7 | 1 | 1,5 | 2 | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

Henan Reach Special Equipment is located in the central city of Zhengzhou, Henan Province, China. Our company is a professional trade supplier of industrial equipment such as boilers, with 12 production companies with various qualifications and over 30 employees. Mainly engaged in the design and sales of oil and gas steam boilers, coal/biomass steam boilers, oil and gas thermal oil boilers, coal/biomass thermal oil boilers, electric heating steam boilers, oil and gas hot water boilers, and medium and high temperature hot air furnaces. The manufacturers our company collaborates with are all legitimate production enterprises with A-level and B-level qualifications for Chinese boiler manufacturing. They have various certifications both domestically and internationally, including CE certification, ASME certification, etc., which can fully meet the matching requirements for boilers in various production environments in different countries. The factories our company collaborates with are all based on the manufacturing and production of various pressure vessels such as steam boilers, thermal oil boilers, and autoclaves. We have established an industrial system that integrates product development, engineering project design, equipment manufacturing, engineering installation, system debugging, pre-sales, sales, and after-sales services. Our company's products are not only sold and widely praised in the domestic market of China, but also exported to more than 60 countries and regions such as South Korea, Vietnam, Myanmar, Mongolia, the Philippines, and Indonesia, receiving recognition and pursuit from customers. I believe that our company can bring objective benefits to customers with advanced technology, excellent equipment, excellent products, and exquisite services. We look forward to long-term friendly cooperation with friends from various countries! Welcome to our store!Q1: What about after sales service, such as installation and commissioning?Answer:(1)English manual, drawings are supplied with boiler. (2)Engineers are able to instruct installing and commissioning abroad.Q2: What are the main products?Answer:(1)Oil fired steam boiler, capacity from 0.1t-20t (2) Gas fired steam boiler, capacity from 0.1-20t (3) Electric steam generator, capacity from 36kw-28800kwQ3: How to insure your product quality?Answer:(1)Strength calculation report with applied materials information; (2)100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; (3)100% X-ray inspection(welding seam): ensure the quality of entire boiler; (4)Hydrostatic test: ensure the standard working pressure and safety; (5)Third-party inspection report; (6)Passed ISO, ASME certifications